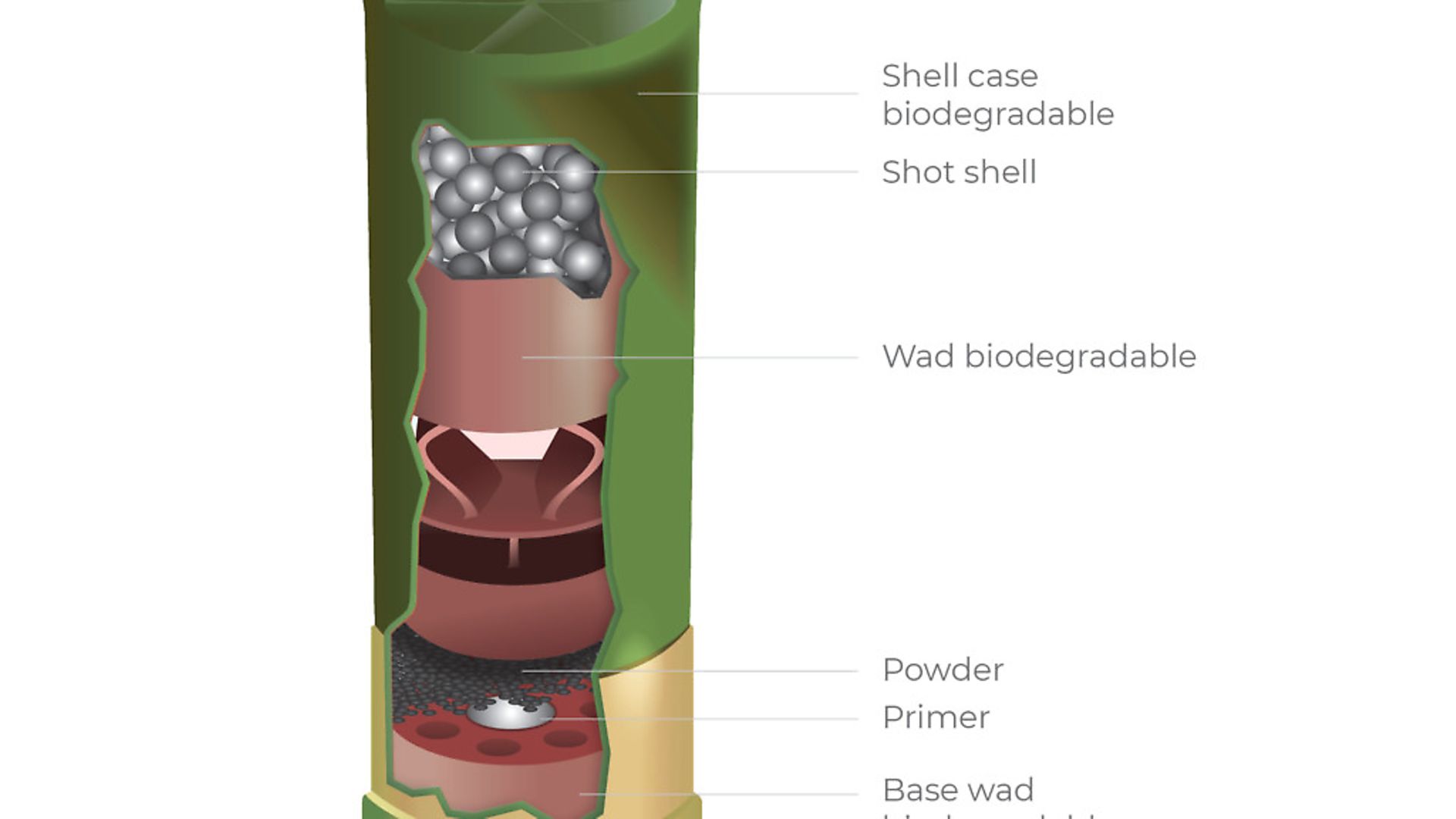

Bioammo’s biodegradable wads AND cases are made with 0% plastic and are 100% compostable, leaving no toxic residue in nature

credit: Archant

credit: Archant

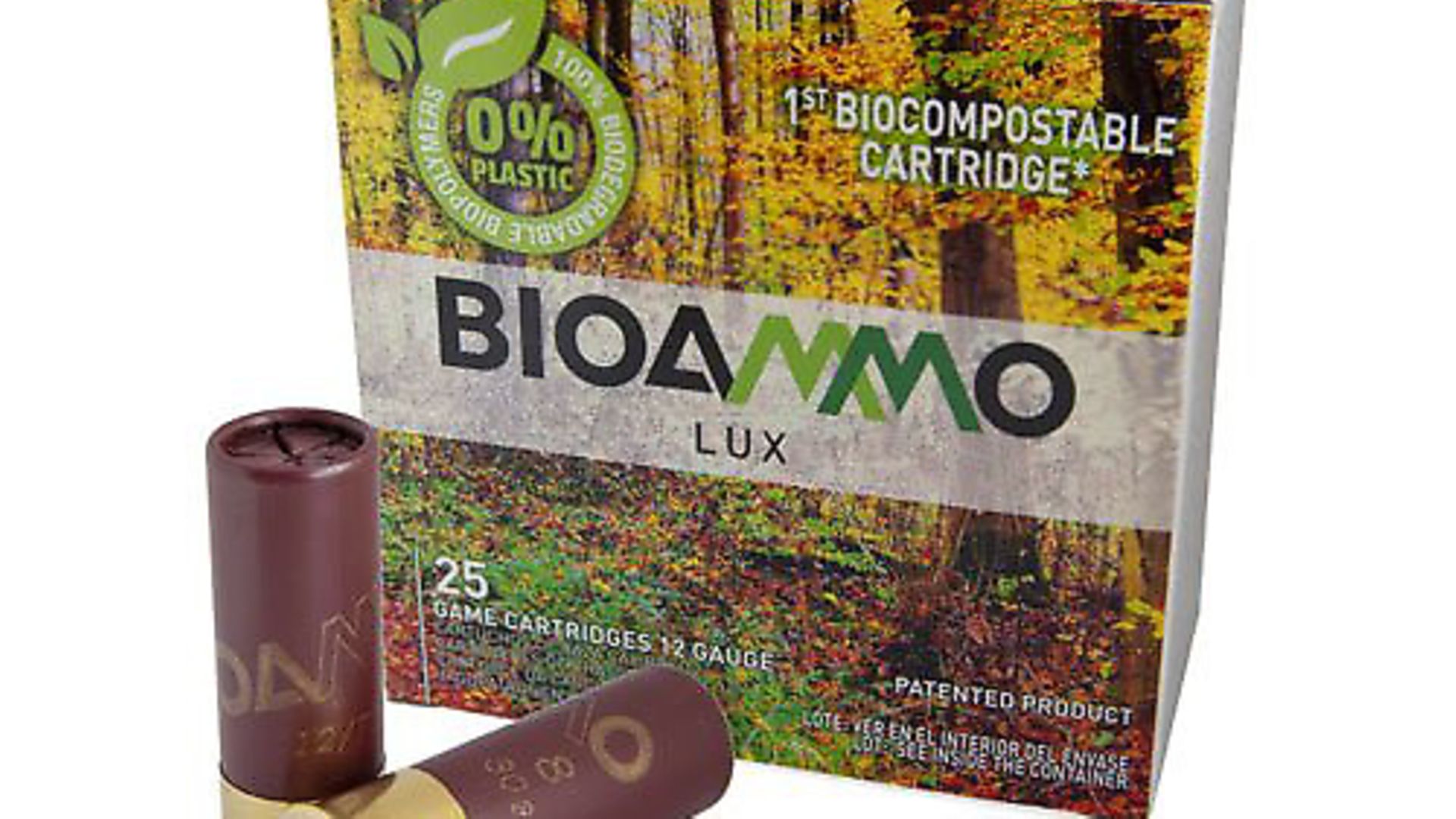

Made in a €13million state-of-the-art factory in Segovia, Spain, Bioammo cases and wads are made with 100% compostable and biodegradable biopolymers that do not leave toxic residues in nature. Bioammo claims it is the only cartridge on the market to have both a biodegradable and compostable case and wad made from a plant-based resin.

Both case and wad break down when they come into contact with the soil as bacteria and enzymes in the ground attack them and turn them in to compost. This process takes around 18 months. The brown wads are very difficult to find after they have been shot, so they will not ruin the shooting ground aesthetic.

credit: Archant

credit: Archant

Because Bioammo’s biodegradable wads and cases are made with 0% plastic, this means there’ll be:

* No production of plastic

* No recycling of plastic

* No dumping of plastic into landfill

* No microplastics to enter the food chain

* No toxic residue that can be left by photodegradable wads that use PVA-based materials

* No additional single-use plastics

* As the material is heavier than plastic, if the wads are shot over a body of water, they will sink and break down in the silt, causing no harm to any wildlife – unlike plastic wads which float.

credit: Archant

credit: Archant

Currently, the cartridges are available in both lead and steel, in a 70mm case:

Steel: 24g No. 7; 28g No. 7; 30g No. 5; 32g, No. 3,4 & 5; 34g No. 3

Lead: 24g No.7½; 28g No. 7½; 30g No. 5, 6; 32g No. 5 & 6; 34g No. 4 & 5

credit: Archant

credit: Archant

67mm cases will be available later this year.

Bioammo BLUE is in final testing stages at the moment. The makers claim this cartridge will be the first 0% plastic, 0% lead, 0% steel cartridge. The shot will be made from a mixture of Bismuth, zinc, tin and aluminium. These will be available in 67mm and 70mm.

RRP: £208, 24g; £212, 28g (lead and steel)

bioammo.es / shootingstarcc.co.uk