The amount and variety of reloading equipment is daunting; Mike Underwood takes a look at which essential bits of kit you'll need to get started with reloading your own bullets...

The press

The press is the centre of your reloading set-up and is also probably the hardest item to choose. If money is no object, you may be tempted to go for a top-of-the-range, fully automated press, but that is not the best way to start, just as it would be a mistake to buy a Ferrari on the first day you start driving.

When you start to reload, you need a press that will allow you to practise each stage of the process individually and learn how to bring it all together to produce safe and accurate ammunition. If speed of production is important to you, then you may be tempted by the faster progressive presses but with that speed, and without the necessary experience, comes a much higher possibility of making dangerous mistakes.

On some presses, it is possible to prime the cases ‘on press’ and this is a good way to keep the whole reloading process self-contained, but if speed is not important, then priming cases off the press is often a better method.

So what are the options when it comes to buying a reloading set-up?

credit: Archant

credit: Archant

Single-Stage Presses: These are the simplest of all the presses, designed to do just one stage of the reloading process at a time, and they will accommodate almost any cartridge size including the huge .50 calibre round. A die is mounted on the press and you work a batch of cases through that die before switching to the next die and processing them again. This is a little bit more time-consuming, but it does allow you to concentrate 100% on the one die. Depriming and resizing, priming, case mouth expanding and bullet seating each require a die switch over.

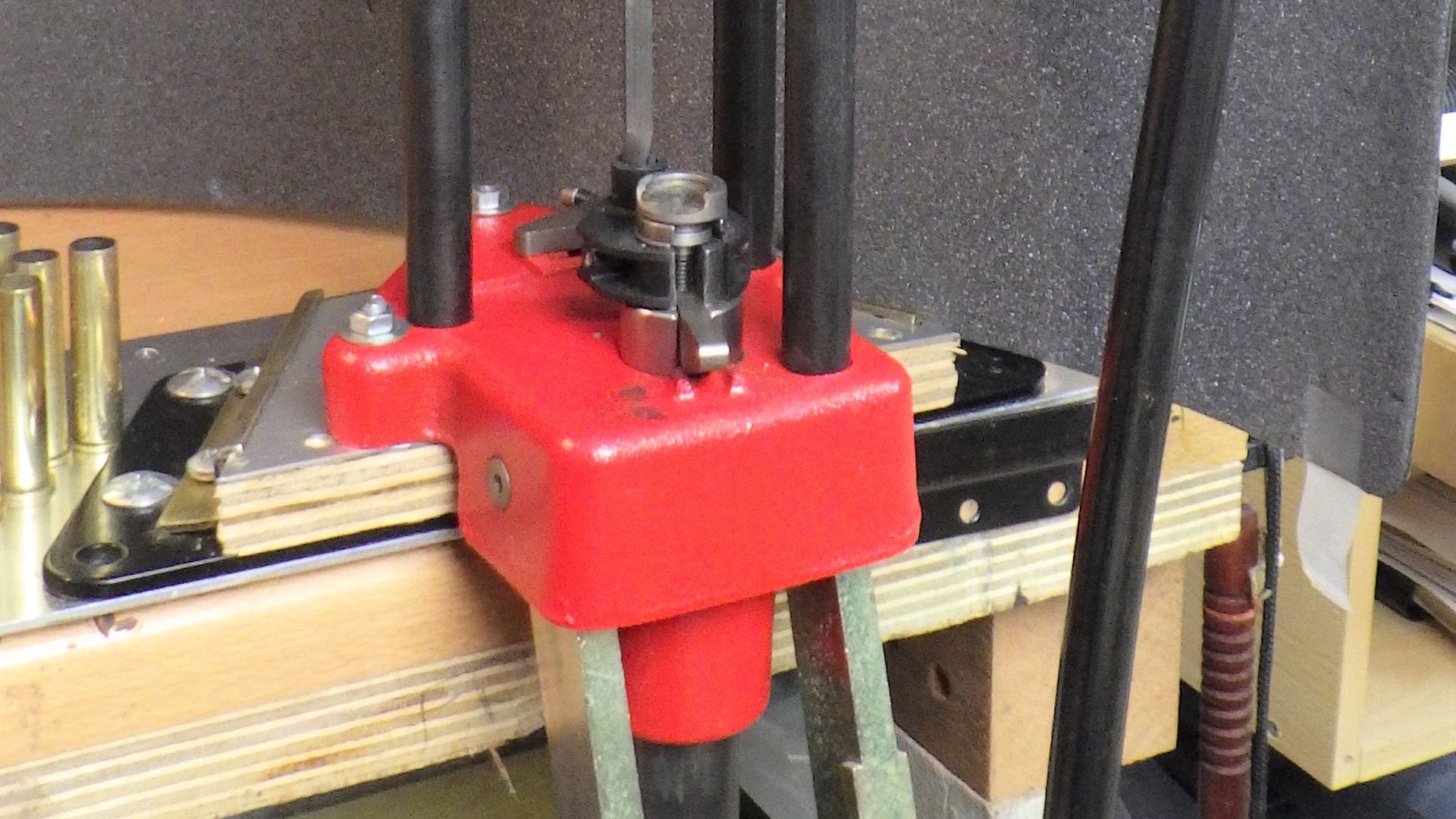

Turret Presses: The centre of this type of press is the turret which holds all of the dies at once, either 3 or 4 depending on the particular press, and as the press is operated each one moves over the case being reloaded and engages with it to carry out its particular task. This type of press can be used as a single stage press with the indexing rod removed and then, after you have mastered each step of the reloading process, you can re-engage the auto-index. This speeds up your reloading considerably as there is no need to unscrew and swap over dies for each stage and on most models the turret advances to the next station automatically. Four pulls of the lever and you have completed a round.

Although intended for moderate speed production of handgun ammunition and smaller rifle calibres, if you deactivate the auto index on a turret press and turn the turret manually you can batch reload the larger rifle cartridges. To swap calibre, just exchange the turret and shell holder and you’re ready to go.

credit: Archant

credit: Archant

Progressive Presses: This basically means fully ‘automated’ presses and they are designed for very high production of handgun-calibre cartridges. If you are a cowboy action shooter eating through a lot of this type of ammunition then these presses can be ideal, AFTER you have mastered a simpler press. Each time you add a bullet and pull the lever, all other operations are automatic and a completed round will drop out of the press. This type of press can handle some rifle calibres, but the automation needs to be disconnected for larger rifle calibres so check before you buy.

Priming: Many presses offer the facility to prime cases on the press, and this is generally the quickest method, but there is a downside to this approach which can lead to issues with primer ignition. Seating primers requires a ‘feel’ for the correct amount of pressure to seat them just right and on automated presses you lose this feel in amongst all of the other stuff going on each time you pull the handle. The best way to feel primers seating is to use one of the hand-held seating tools.

Dies

The dies are the calibre-specific ‘tools’ that actually come into contact with the components and process them into completed rounds. You will need a set for each calibre that you intend to reload and good quality dies should last you a lifetime. Dies can be purchased in complete sets or individually and the price and content of the sets does vary considerably from brand to brand. Some offer full-length sizing dies which, as the name suggests, squeeze the entire length of the cases back to standard dimensions and some offer neck-sizing only. These resizing options will be considered later but both have advantages so a set of dies that includes the two options is worth the additional cost. Not all die sets include a shell holder, which is a vital little item so be sure that either one is included or you purchase one separately.

Scales

A good quality set of scales is definitely a necessity, with checking powder charge weights being one of the most important safety requirements in reloading. Even if you are using a powder measure that dispenses charges by volume, you MUST check the weight of the charges when you set up the measure and regularly when reloading. There are two options: beam scales that use the ‘old fashioned’ balance method of weighing, and digital scales that display the weight of whatever is placed on the tray on a small screen. Beam scales are more difficult to set up, and can be easily knocked out of adjustment so need to be checked regularly, but they are very accurate. Digital scales are faster to set up and use, but they do need to be recalibrated often to ensure they have not drifted out of zero. You are working with very small weights so accuracy and consistency is very important and it is worth investing in decent scales. Although it is not necessary at the outset, further down the line it is actually worth investing in both types of scale so that you can check them against each other regularly to ensure they are accurate.

credit: Archant

credit: Archant

Powder Measure

There are many powder measures available on the market, and covering all the options would take up an entire article on its own, but it is possible to start reloading by weighing out each charge individually on the scales and this is certainly the safest way to start. Some die sets include a powder scoop and this is really useful for placing powder onto the scale safely.

Accessories

There are hundreds of accessories that you can add to your set-up, some of them being necessary and others just being useful to have.

The Cartridge Overall Length is a critical factor when making your own ammunition and a good quality dial caliper is absolutely vital so you can check the length of your rounds. Smaller items like loading trays, ammo boxes, priming tools and case lube are also well worth purchasing as a part of your initial set-up.

credit: Archant

credit: Archant

Mike’s Recommendations

Opinions on what is the best gear to buy will vary according to who you ask, and everyone has their preference on brand, but here is my recommendation:

Lee Precision make some of the best value and quality reloading gear available here in the UK and one of their single-stage presses is a great place to start. Alternatively, if you prefer to go straight to a press with the option for some degree of automation, their Classic Cast Four Hole turret press is also a great choice.

For reloading rifle calibres, a progressive press is not recommended. When it comes to dies, with the Lee Precision Ultimate Rifle Die Set (or something equivalent) including both full-length and neck-only sizing dies, shell holder, powder dipper and load data, you cannot go wrong and you have all your options covered.

For weighing powder charges, the Reloader Marksman digital scales work extremely well and accurately or, if you prefer a more traditional scale, the Lee Safety Scale is certainly one of the cheapest yet most accurate balance scales you can get.

A good quality hand priming tool is well worth investing in, with the Lee Auto-prime currently my weapon of choice, although RCBS also offer a great quality equivalent tool.

There are also complete ‘starter kits’ available which include everything except dies, and they are well worth considering being cheaper than buying items separately.

Contacts: Lee Precision reloading equipment and Henry Krank & Co. Ltd